Logistics transportation ceramic tile which need to be paid attention to

by:Overland ceramics

2020-10-22

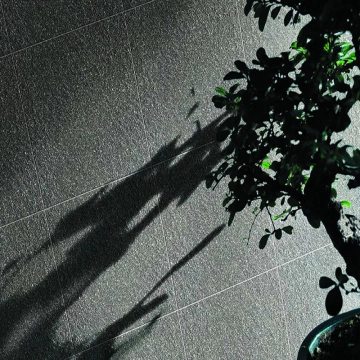

Floor tile a logistics company can transport.

But there must be a normal wear and tear on the way, this and the goods should be mentally prepared.

(

Logistics tile)

Logistics is to point to in order to meet the needs of customers, at the lowest cost, through transport, storage, distribution, implementation of raw materials, semi-finished products and finished products or related information from origin of goods to the commodity consumption plan, implementation and management of the whole process.

Logistics is a control of raw materials, finished products, finished goods and information system, starting from the supply by all kinds of the transfer of the intermediate links and has reached the final consumer of physical exercise, in order to achieve specific goals of the organization.

Modern logistics is the product of economic globalization, it is also an important service industry to promote economic globalization.

The consignment process need to pay attention to what issues?

First is a carrying, no violence to carry, ceramic tile when transporting ceramic tile should be light to take light put, place of ceramic tile also should be parallel to the ground, it is prohibited to use single Angle to carry on the way to ceramic tile.

Box ceramic tile transport stack should comply with the relevant principles, namely is heavy pressure light, and ceramic tile can't parallel stacking, ceramic tile should be placed vertically stacked way, ceramic tile pile up not too high, avoid because the bumpy road condition causes damage in transit.

To improve of ceramic tile product packaging, the packaging should be used the whole package, will be completely packaging, the four edges and corners to use thicker plastic material for special protection, packaging material selection use wear resistance better paper material as far as possible, or increase the thickness of paper.

In the transport of ceramic tile choice as far as possible choose direct logistics, logistics to avoid more link flow handling result in breakage.

Extension materials: ceramic tile quality problem is not the main cause of the ceramic tile damaged, ceramic tile failure mainly occurred in the process of handling and transportation, especially when forklift pick is not standard, the use of one foot on the way to carry on ceramic tile, and ceramic tile product also has effect on the stacking way, on the other hand, is ceramic tile product outer packing way also some relationship.

Ceramic tile damaged common position: 1, the four tiles are generally four Angle of rupture, or see more of this kind of situation is usually caused by handling is not enough light to take light put, some may also be a manufacturer of packaging when no Angle, but no little corner protector.

Normally, a four Angle of covering damage, rupture, and general porter, it is generally a novice carrying, or energy can't carry killed small ceramic tile.

So, usually, to warn a porter to should take put down gently, try not to use four support on the ground.

2, fracture rupture in the middle, and the ceramic tile or Angle of fall, it is broken, belongs to the ceramic tile rupture of serious, such cases, to see whether the ceramic tile damaged how much is the proportion of total goods, beyond the prescribed proportion can ask manufacturers, distributors and logistics survey, present a fracture toughness is the root cause of ceramic tile is not up to standard.

Or collapsed appeared in the process of logistics, bumps, etc, put forward the appropriate compensation.

Similar situation, general but from logistics to find the answer, if hit, depends on a correct way, a right way, can cause the fracture of ceramic tile;

If there is no play, ceramic tile loading way is tile press, tile tile pressure is overweight, ceramic tile is perceptible, etc.

3, surface crack,

Glaze cracks)

Ceramic tile from the surface or crack of glaze layer, it is divided into two cases.

One is, whether as a result of scratching by the external force, or a collision, cause the ceramic tile surface rupture, but have not broken into bricks.

Two is that the glaze of ceramic tile itself is unqualified, or the compressive heat resistance of ceramic tile is not enough, did not achieve the result of vitrified, ceramic tile appear crack.

Situation, please factory quality after-sales personnel, quality inspection personnel related batch products inspection, whether the quality pass, etc.

If the quality is no problem, we should see whether products by other physical effect caused the damage.

(

Logistics tile)

Guangdong Overland Ceramics Co., Ltd have expanded from facilitating conversation and collaboration in the identity industry to providing strategy consulting services, research, analytics and education.

See reviews of the latest trend in tile company industry at Overland Ceramics, and see the best that work in just minutes! Visit us right away!

As the full potential of ceramic floor tile lies in , the demand for is increasing globally, and is being adopted across the global market.

Guangdong Overland Ceramics Co., Ltd have expanded from facilitating conversation and collaboration in the identity industry to providing strategy consulting services, research, analytics and education.

See reviews of the latest trend in tile company industry at Overland Ceramics, and see the best that work in just minutes! Visit us right away!

As the full potential of ceramic floor tile lies in , the demand for is increasing globally, and is being adopted across the global market.