The balcony ceramic tile development of rendering process details

by:Overland ceramics

2020-09-05

The balcony the development of ceramic tile rendering process details are now many young people very favour.

On the balcony the development of ceramic tile rendering process details of the topic is very popular.

Next let small make up to you arrangement about the development of ceramic tile rendering process details the contents of the balcony, want to be able to let everybody know more detail about the development process of ceramic tile details.

The history of how technology development: ceramic tile ceramic tile should be traced back to BC, at the time, egyptians have begun to use ceramic tile to decorate the various types of housing.

People will be dried in the sun or clay brick it by using the method of baking drying, and then use copper from blue glaze color.

BC, Mesopotamia region also found the ceramic tile.

This kind of ceramic tile to be blue and white stripes for decorative purpose, appeared a variety of styles and colors more later.

China's ceramic art, as early as the shang Yin period to produce a beautiful white stoneware.

In ancient times, are all made by hand.

That is to say, every piece of ceramic tile is manual molding and colored by hand, so every piece of ceramic tile is a unique work of art.

Now, full range, is to use automated production technology, the hands of those who are only used for operating equipment.

In the past, indoor and outdoor use ceramic tile to decorate.

Ceramic tile shop sticks how technology development: 1, the well-known modern ceramic tile production skills and equipment both originated in Europe, the ceramic tile of domestic produced depends on Europe (

The first in Spain, Italy)

The skills of formulation and production equipment support, has long been European ceramics China will all learn domestic manufacturer first skill hall in Europe.

2, not nine of 10 s of the last century, in order to deal with domestic production skills defects and shortcomings are sold, manufacturers launched after trimming, the wall brick (

Ceramics)

Rise, guides the market customers, seamless shop is stuck.

3, therefore, that is, the domestic manufacturer producing skills behind the wall brick production process is very difficult to control, briefly presents the large scale error and flatness are rugged landscape, is particularly big standard goods, cannot be directly the shop is stuck, so domestic manufacturer will already be products of wall tile, add the procedure & ndash;

—

Edge grinding (

Also known as the trimming)

Makes the wall brick of the factory are straight goods, thus promote seamless shop is stuck at the mall.

Sort out the above content is the small make up to you about the details of the technology of the development of ceramic tile, hope we can have a good reading, to avoid unnecessary mistakes.

Guangdong Overland Ceramics Co., Ltd is willing to push up our sleeves and wade into unknown territory with equal parts fearlessness and optimism.

Overland ceramics is the vital link in the supply chain, adding value with efficient and cost-effective service and solutions for our customers and our suppliers.

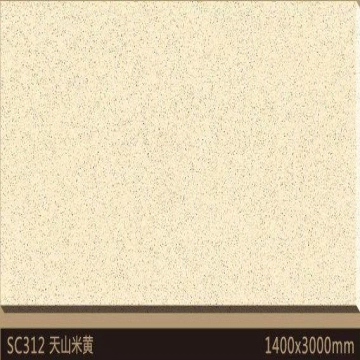

Overland ceramics provides a number of ceramic floor tile designed to handle ceramic floor tile.

Guangdong Overland Ceramics Co., Ltd is willing to push up our sleeves and wade into unknown territory with equal parts fearlessness and optimism.

Overland ceramics is the vital link in the supply chain, adding value with efficient and cost-effective service and solutions for our customers and our suppliers.

Overland ceramics provides a number of ceramic floor tile designed to handle ceramic floor tile.