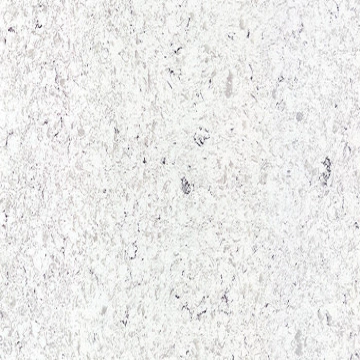

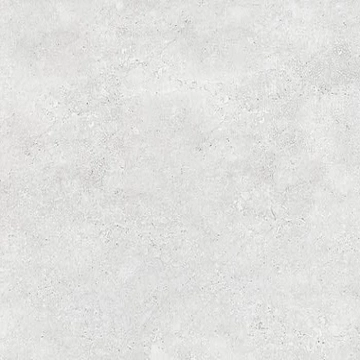

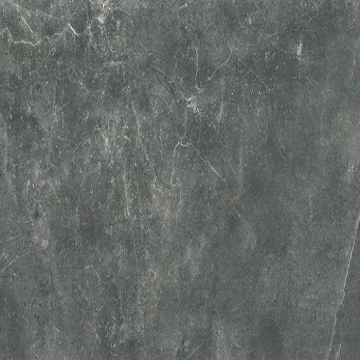

The kitchen ceramic tile of white ceramic tile rendering mold

by:Overland ceramics

2020-12-05

Recently, small make up received a lot of white ceramic tile rendering about the kitchen ceramic tile mould question, for the kitchen white ceramic tile ceramic tile of rendering mould also some kind of understanding, the following is about the kitchen white ceramic tile rendering to you talk about the details of the ceramic tile mould, hope these can help to you.

Technical implementation elements: therefore, in view of the above problems, the utility model provides a kind of ceramic tile mould, it mainly solves the existing technology in manufacture different specifications of ceramic tile, ceramic tile mould replacement to the problem of high cost.

To achieve the above purpose, this utility model adopts the following technical scheme: a kind of ceramic tile mould, including backplane, backplane described set on medium plate, set on the plate are described under magnetic suction, surround described under magnetic suction side of a week is located in the floor set several columns, described in the column set on frame, frame described in the magnet on the set has at least one upper trough, described on the frame is located in the tank wall set a side panel, as described through a setting tank has a lower die core, described in the lower die core and side plate clearance fit, as described in the fixed mold core under the above magnetic suction seat, which described the mold core and side plate cavity with some holding space is formed between, described the frame on the table in the cavity of the weeks side removable set with special-shaped pieces.

Further, described on the lateral plate is located in the mold cavity inlaid alloy block.

Described further, with the top of the column between the frame and set a block adjustment.

Further, frame including fixed set on columns of frame and removable bridge on the connection of the frame, special-shaped panel board can remove the set in the connection seat.

Further, described the number of slot into two.

Further, special-shaped blocks including from left to right in turn interval set left plate, medium plate, and the right board described left plate body and medium plate body and the plate between the body and the right plate body all have connection plate connection Settings, described the left plate, medium plate, the body from the right and the connecting plate formed between two slot corresponding to the opening, described the connection plate set several side by side on the half ball.

By adopting the technical proposal, the utility model is beneficial effects: the ceramic tile mould, the production of different specifications of ceramic tile, by changing and ceramic tile structure to match the special-shaped set piece, in the process of cloth car cavity for cloth, cloth of the powder on scraper with cloth car, due to the powder scraper under its own gravity has to depend on the frame of the above-mentioned movement, by changing the abnormity edge shape, making powder scraper movement change, and to remove the excess powder, cavity is conducive to mold pressed into the ceramic tile of different specification, avoid the replacement of the frame, so as to effectively reduce the cost of replacement when ceramic tile die;

Further, on the side panel is located in the alloy block embedded in the mold core, make the side panel of hardness and wear resistance, avoid the side panel powder in the process of pressing hard extrusion with the side panel is damaged, to improve the use of the side panel birthday noodles;

Further, with the top of the column between the frame and set the regulating block, adjusting the module level, to adjust the mold core and mold core pressing on the distance, to adjust mould pressing force;

Further, the frame are connected by a detachable frame bridge and connection, when only changing thickness size, only need to replace the aliens on the frame panel board and side board, make the side panel and the lower die core surrounded by cavity thickness change, under the replacement time of lower die core and less production cost of the mold core, effectively reduce the cost of replacement when ceramic tile die;

Further, set up the left plate, medium plate, the body from the right and set up several half ball bump connection board side by side, making special-shaped panel board production is simple, reduce the processing cost, and is conducive to mold positioning clamping.

Above is the small make up finishing for everybody to decorate some of the more important content, hope to be able to help to the owner's friends in need.

Guangdong Overland Ceramics Co., Ltd's products, whether interim or permanent, comply fully with all appropriate producing regulations.

With continuous operational improvements, expanding capacity and a strong competitive position for serving strategic domestic markets, Guangdong Overland Ceramics Co., Ltd are positioned for long-term growth that will benefit our customers and investors.

tile company are raising the stakes of social marketing, but they also ease the sales process by providing ways for ceramic floor tile to effectively interact with customers.

There is growing awareness about the health benefits of among the consumers resulting in its increasing popularity.

Guangdong Overland Ceramics Co., Ltd's products, whether interim or permanent, comply fully with all appropriate producing regulations.

With continuous operational improvements, expanding capacity and a strong competitive position for serving strategic domestic markets, Guangdong Overland Ceramics Co., Ltd are positioned for long-term growth that will benefit our customers and investors.

tile company are raising the stakes of social marketing, but they also ease the sales process by providing ways for ceramic floor tile to effectively interact with customers.

There is growing awareness about the health benefits of among the consumers resulting in its increasing popularity.