Details about ceramic tile stick wall

by:Overland ceramics

2020-12-24

Details about ceramic tile stick wall, many owners may not be familiar with, small make up recently happened to learn about some information about ceramic tile stick wall details, for everyone here to introduce experience about ceramic tile stick wall details, hope can help to you.

Method 1 stick ceramic tile.

Before shop sticks ceramic tile, need to sweep the ground level off clean, generally need to use the render 1:3 cement mortar, the thickness of the base is usually 6 mm.

Then its metope should give metope stick ceramic tile microstrip MAO, but also must be smooth.

First need to ceramic tile blocks calculated, then the level set points.

Render to every 3 to 4 days after completing a job the ceramic tile paste is begun.

2.

Stickup ceramic tile need we will wall wet with water first, and then at the bottom of the ceramic tile of the ground floor of a mat feet plate to put good, it is important to note pad foot plate must keep horizontal line, then should be fixed well.

Need stickup ceramic tile should remove it after soaking water slightly air-dried, then follow the mat feet along the paste on the board.

3.

In the 1:2 cement sand add right amount 107 glue, 3-4% can improve workability of mortar.

Slow down the setting time.

To facilitate paste and prevent slurry flow.

Affix mortar at the back of the tile, the wall with a rubber mallet tap brick surface, the mortar was crowded.

4.

After the bottom layer of ceramic tile, by feet vertically as vertical standard.

They usually begin from Yang Angle, so that not a whole piece of ceramic tile seam alignment.

Need to be vertical and horizontal seam alignment, tile surface is stained with mortar should be erased when in did not work, after the post rinse wipe, dry nuiko with white cement.

How much is the sand stick ceramic tile gray scale 1.

The ratio of cement and sand is 1 to 2, and in conformity with the relevant provisions of the state, if lower proportion, more concrete, more can enhance the cohesive force, in the tile wall brick, the proportion of 1 to 1 can be used mixed cement and sand, but not clever so would increase the cost of part, so the cement must note in advance.

2.

Shop to stick floor tile, the ratio of two materials can increase to 1 to 2 or 3 to 1, because most of the houses is leveling with cement mortar ground handling, when laying floor tile so don't use too much cement which can play a strong role.

3.

At the same time, to prevent excessive cement shrinkage caused large tensile stress cracking of ceramic tile, appropriate USES low grade cement.

Above is the small make up for everybody finishing some information about the details of ceramic tile stick wall, everyone if in doubt can also login our website to query.

To live up to our responsibilities to serve and enhance the communities in which Guangdong Overland Ceramics Co., Ltd works and lives and the society on which we depend.

Guangdong Overland Ceramics Co., Ltd’s goal is to provide the customer with an enjoyable, honest service by satisfying individual customers practical transportation needs with a quality product.

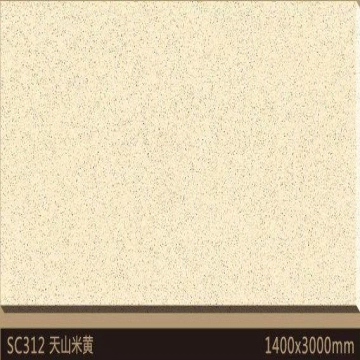

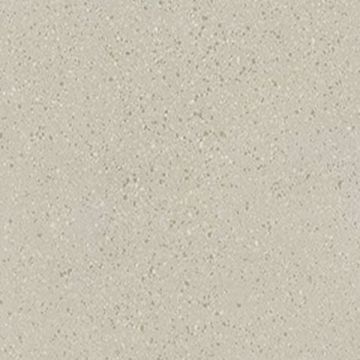

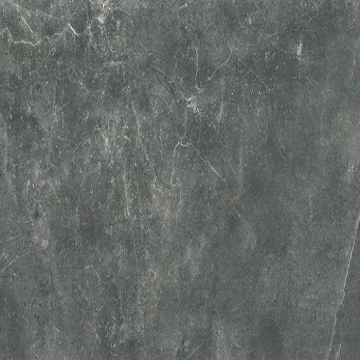

Producing with varied technical skills, tile company can be used in a wide range of applications as ceramic floor tile.

Guangdong Overland Ceramics Co., Ltd has an excellent staffs who will guide you with their best ideas by keeping in constant touch with your company and informing about the market trends.

There are so many factors that businesses have to weigh when producing tile company, and we are not going to pretend to grasp all of them.

To live up to our responsibilities to serve and enhance the communities in which Guangdong Overland Ceramics Co., Ltd works and lives and the society on which we depend.

Guangdong Overland Ceramics Co., Ltd’s goal is to provide the customer with an enjoyable, honest service by satisfying individual customers practical transportation needs with a quality product.

Producing with varied technical skills, tile company can be used in a wide range of applications as ceramic floor tile.

Guangdong Overland Ceramics Co., Ltd has an excellent staffs who will guide you with their best ideas by keeping in constant touch with your company and informing about the market trends.

There are so many factors that businesses have to weigh when producing tile company, and we are not going to pretend to grasp all of them.